Some of the Industries we work with

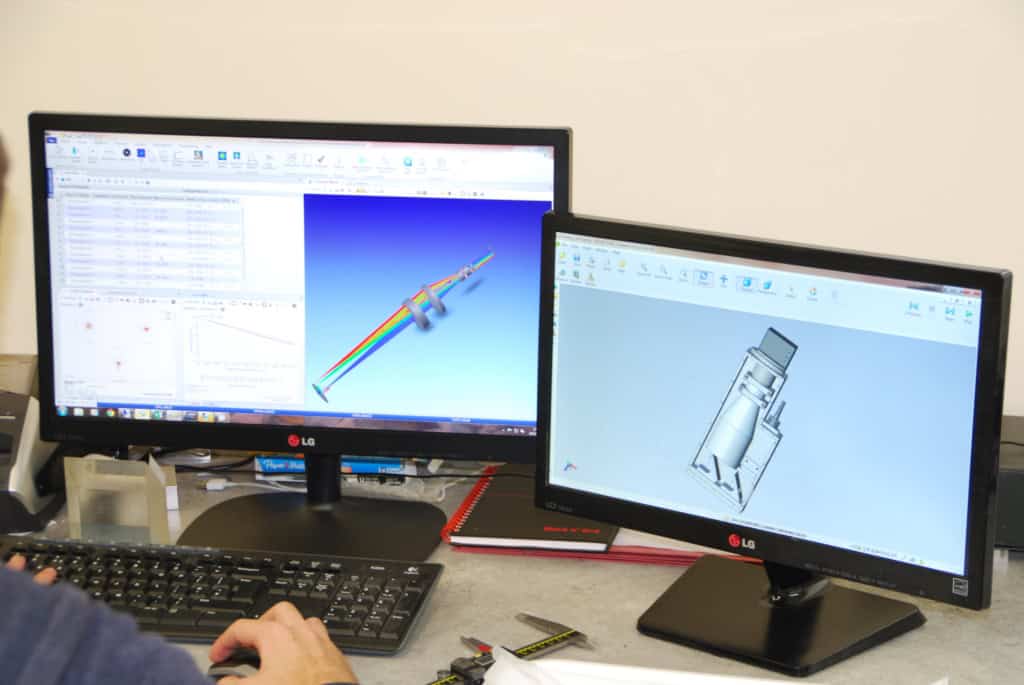

From Specs to Simulated & Tolerance-Checked Designs

At Kingsview Optical, we deliver flexible optical design services tailored to your project needs — from full prototype-to-production solutions to design-only support for external manufacturing.

Designed with manufacture in mind

We don’t just design for theoretical perfection—we design for performance that can actually be built.

Unlike most optical design firms, Kingsview Optical carries out the entire process under one roof—design office and manufacturing floor.

That first-hand production insight lets us create high-performance systems that hit both your timeline and your budget. Too often we see “perfect-on-paper” designs whose tight tolerances collapse in the real world. By designing side-by-side with the engineers who will machine the parts, we keep performance realistic, manufacturable, and ready to deliver.

How it works

Example Applications

A snapshot of the range of lenses we have designed through to manufacture

Custom Liquid Lens Objectives

SWIR Objectives

Fluorescence Microscopy Objectives

Telecentric Lenses

Machine Vision Lenses

Borescopes

Why Design with Kingsview?

When design and production talk daily, your project stays on spec, on time, and on budget.

Typical Firm

Kingsview Optical

Smarter Budgets

Optical design software can optimise for theory—but not for real-world buildability or cost.

It won’t warn you if a lens geometry is tricky to polish, or if a “better” glass will double your reject rate.

That kind of judgment comes from experience on the manufacturing floor.

We design with performance in mind—and with both feet in the realities of manufacturing—so your system delivers maximum value without unnecessary cost.

Rapid Fixes

Even with the best design and planning, things can go sideways. The difference?

We’re right here.

No overseas delays, no third-party waitlists, no shipping optics back and forth.

If something needs correcting, it gets done in days—not months—because our engineers, machines, and metrology tools are under the same roof.

That means faster resolutions, fewer surprises, and the confidence of knowing you’re always a priority.

Trusted Since 1996

We’re proud to have been serving our customers for nearly three decades. Since 1996, Kingsview Optical has partnered on a wide range of challenging and high-precision projects across multiple industries.

Our clients include respected organisations such as Mahle Engine Systems, the National Physical Laboratory (NPL), and the Francis Crick Institute, with whom we collaborated on a key optics project that contributed to a published scientific paper—read it here ›.

From R&D breakthroughs to mission-critical assemblies, our work stands behind some of the UK’s most innovative scientific and engineering teams.

Have a project in mind?

Let’s explore how we can design and deliver it—on time, on budget, and ready for production.